A LIMERICK-based medical devices manufacturer has made a “breakthrough” in the manufacturing of 3D-printed implants, which could lead to significant steps forward in the medical devices, industrial, and energy sectors, as well as health benefits for people in need of implants.

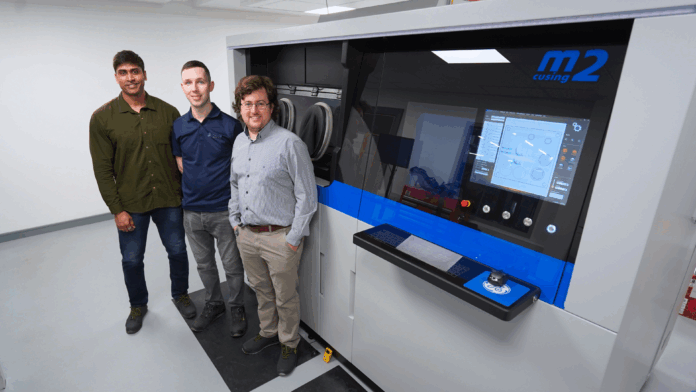

Croom Medical this week announced the launch of its new Talos technology platform – a project designed to 3D-print tantalum components using advanced laser-powder-bed fusion and “setting a new standard in the industry”.

Tantalum is a hard, ductile, transition metal that is highly corrosion resistant and, as such, renowned for its biocompatibility and suitability in the manufacturing of medical implants.

Prior to now, Croom Medical said, significant challenges have prevented its widespread industry use. The new Talos platform, a statement read, “overcomes these obstacles, enabling the production of complex, porous, strong, and lightweight tantalum structures for medical device and industrial applications”.

Dr Shane Keaveney, R&D manager at Croom Medical, highlighted the significance of the advancement, stating that “tantalum has long been valued for its outstanding biointegration, corrosion resistance, and mechanical properties. With Talos, we unlock these intrinsic qualities, allowing precise control over implant ductility and strength to closely match native bone”.

“A standout feature of Talos is its ability to directly print tantalum onto titanium substrates, merging titanium’s lower density with tantalum’s osteoconductive prowess. This hybrid approach holds the potential for implants with enhanced bone fixation, representing a significant step forward in reducing the need for revision surgeries,” a statement from Croom Medical explained.

The added durability of tantalum, Croom Medical believes, will “lower the rate of surgery revisions” from implants, “thus avoiding patient discomfort and unnecessary added surgery costs”.

The company further explained that “beyond medical applications, Talos offers significant advantages for the industrial and energy sectors”.

“Its ability to craft complex near-net shape components incorporating advanced design features such as controlled porosity zones, cellular lattices, surface textures, and internal cooling or mixing channels, unlock efficiencies in demanding applications in power generation, chemical processing, and high-temperature operations.”

Dr Keaveney concluded that “the launch of Talos positions us at the forefront of medical innovation, reinforcing our commitment to continuous innovation and advanced patient care”.